Jim Dodd

LOVES Wooden Canoes

This Summer I used my solo stripper build ( Pearl ) as a male mold for a Carbon/Kevlar composite build. I named this canoe Black Pearl.

Here's a few pics.

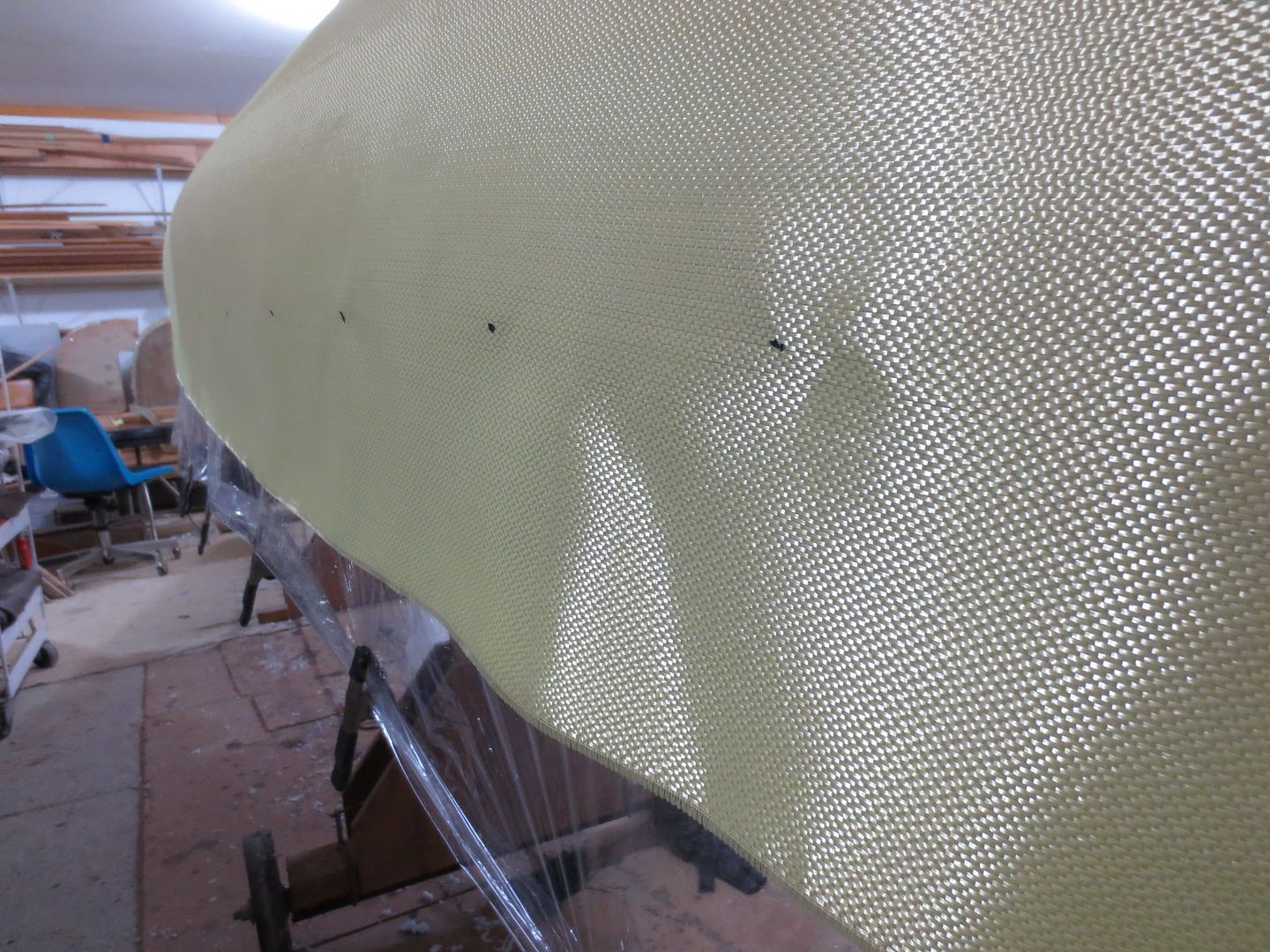

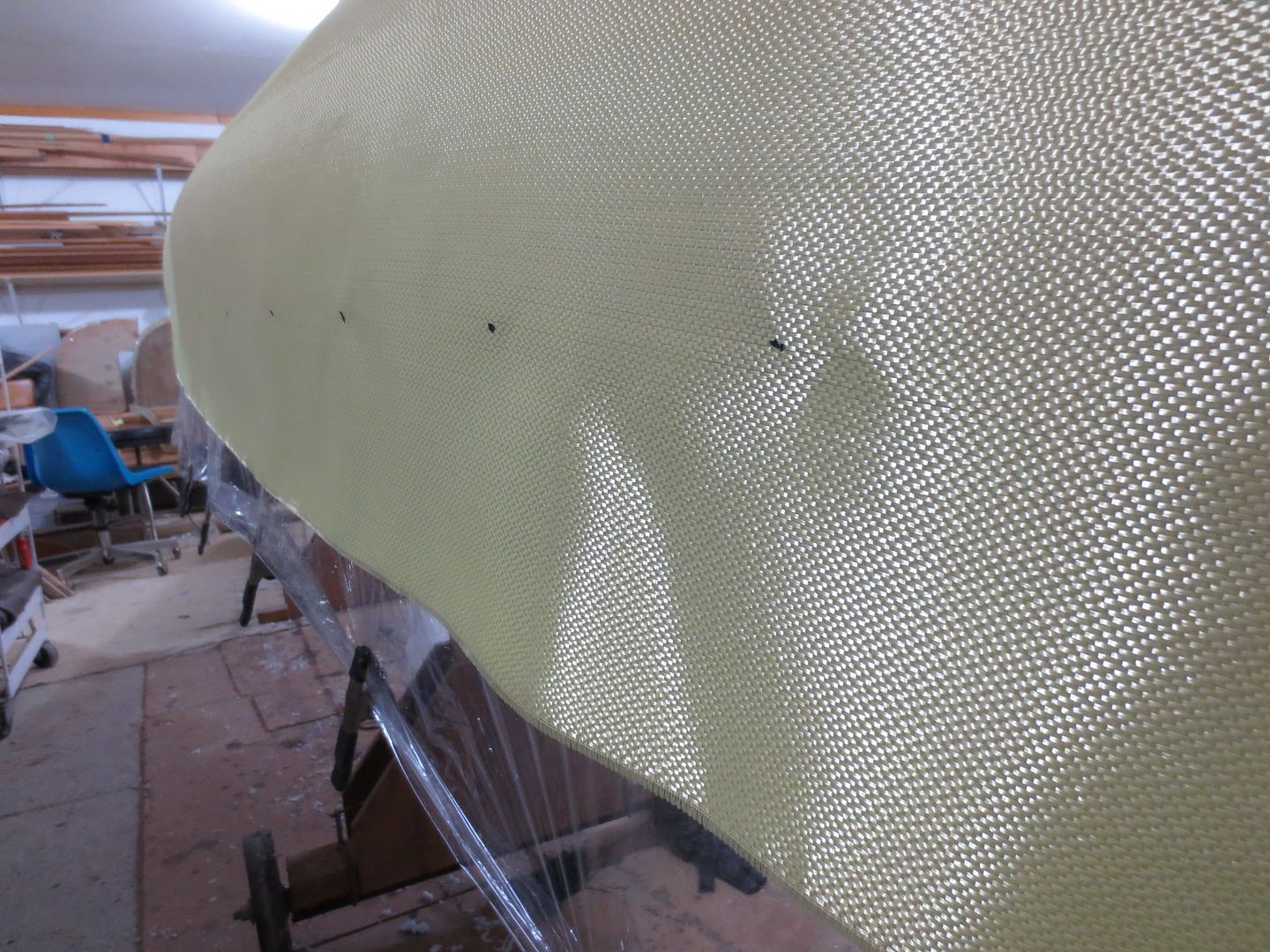

Covering the stripper with Heat Shrink plastic, and the stems with Electricians tape, as a barrier between the two hulls.

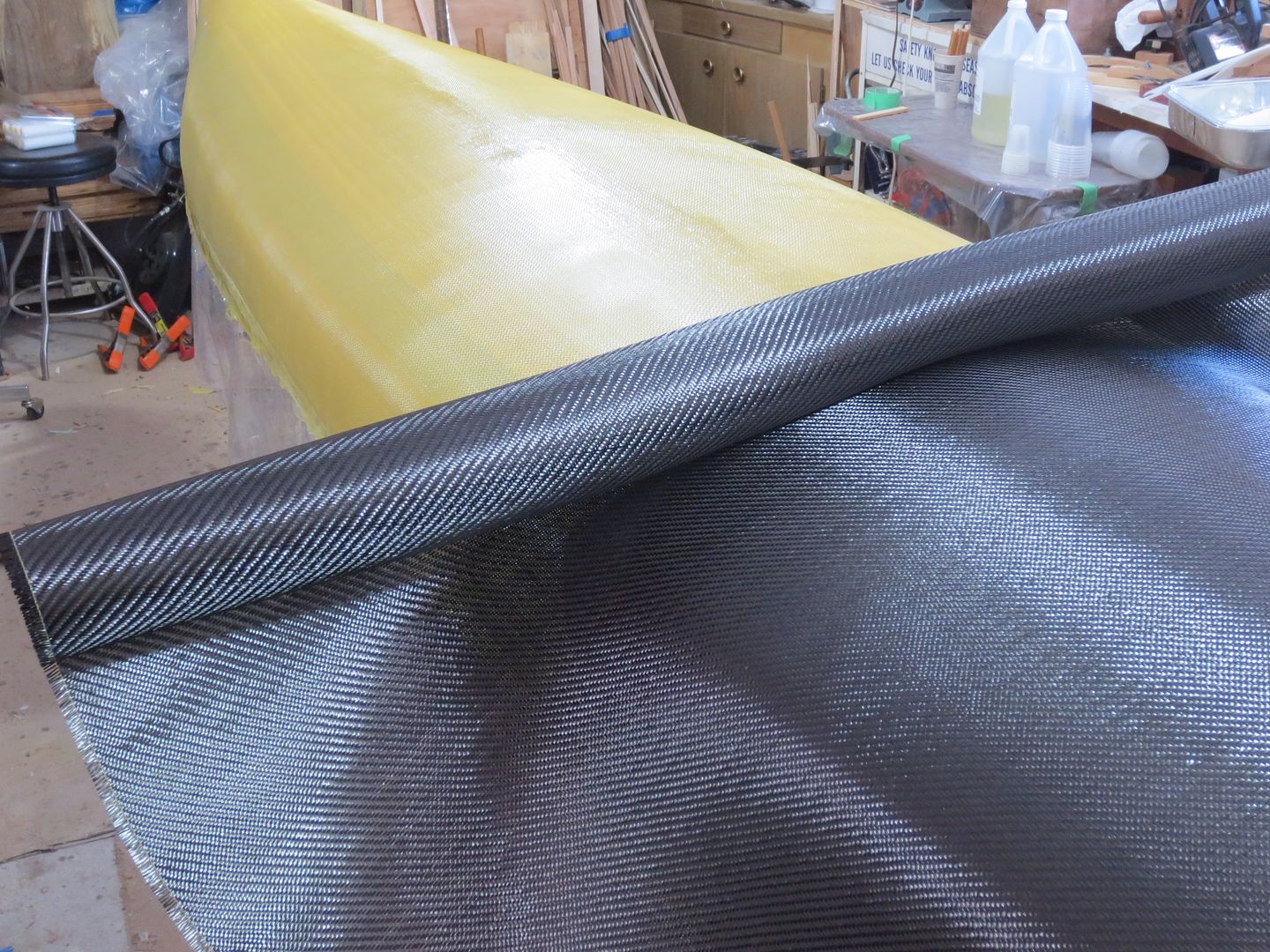

Marking where to cut the Kevlar.

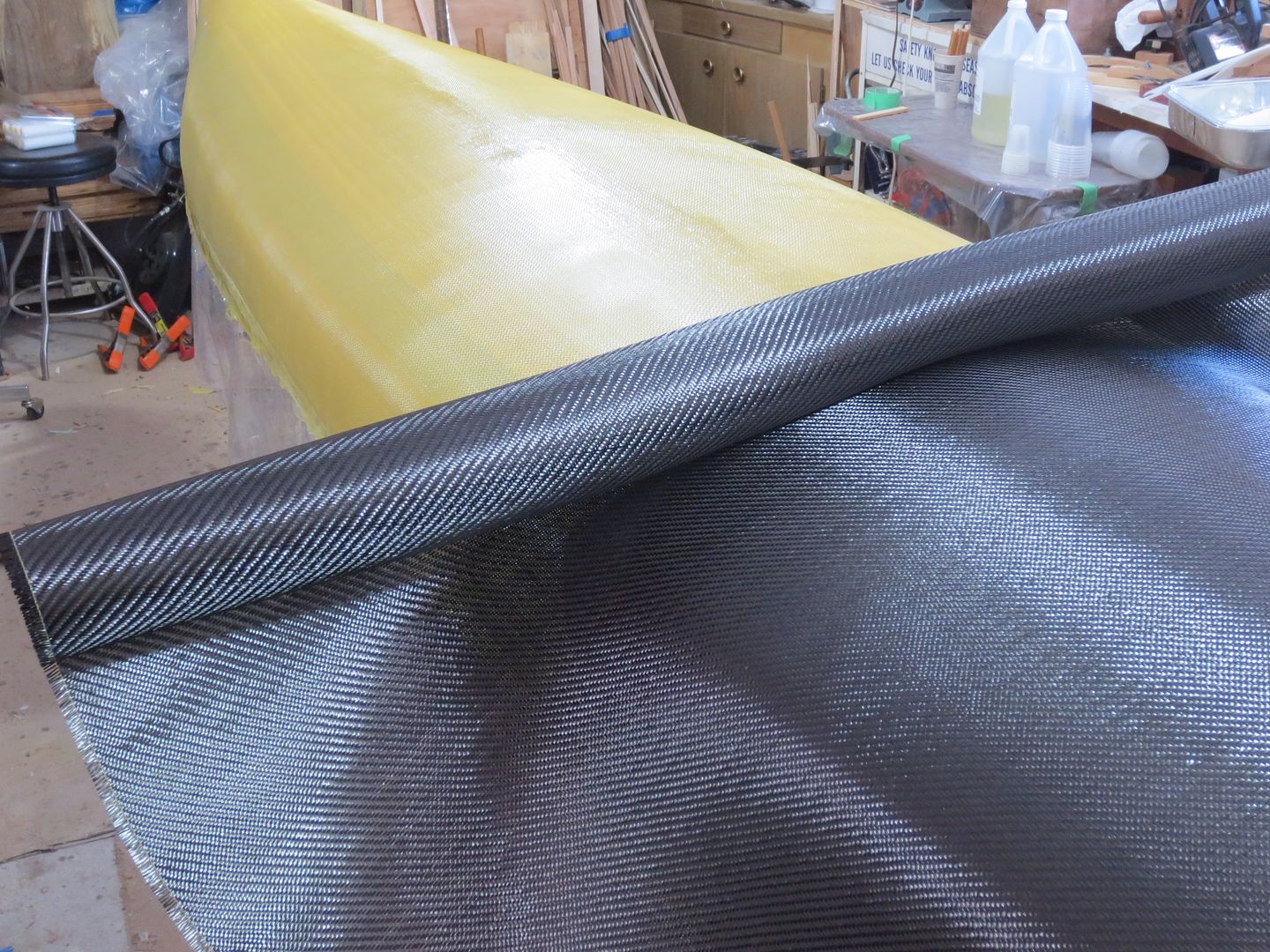

At this point, I have 3 layers of cloth make up the hull. One 5 oz Kevlar, one 6 oz Twill Carbon fiber, and one 6 oz S-glass,

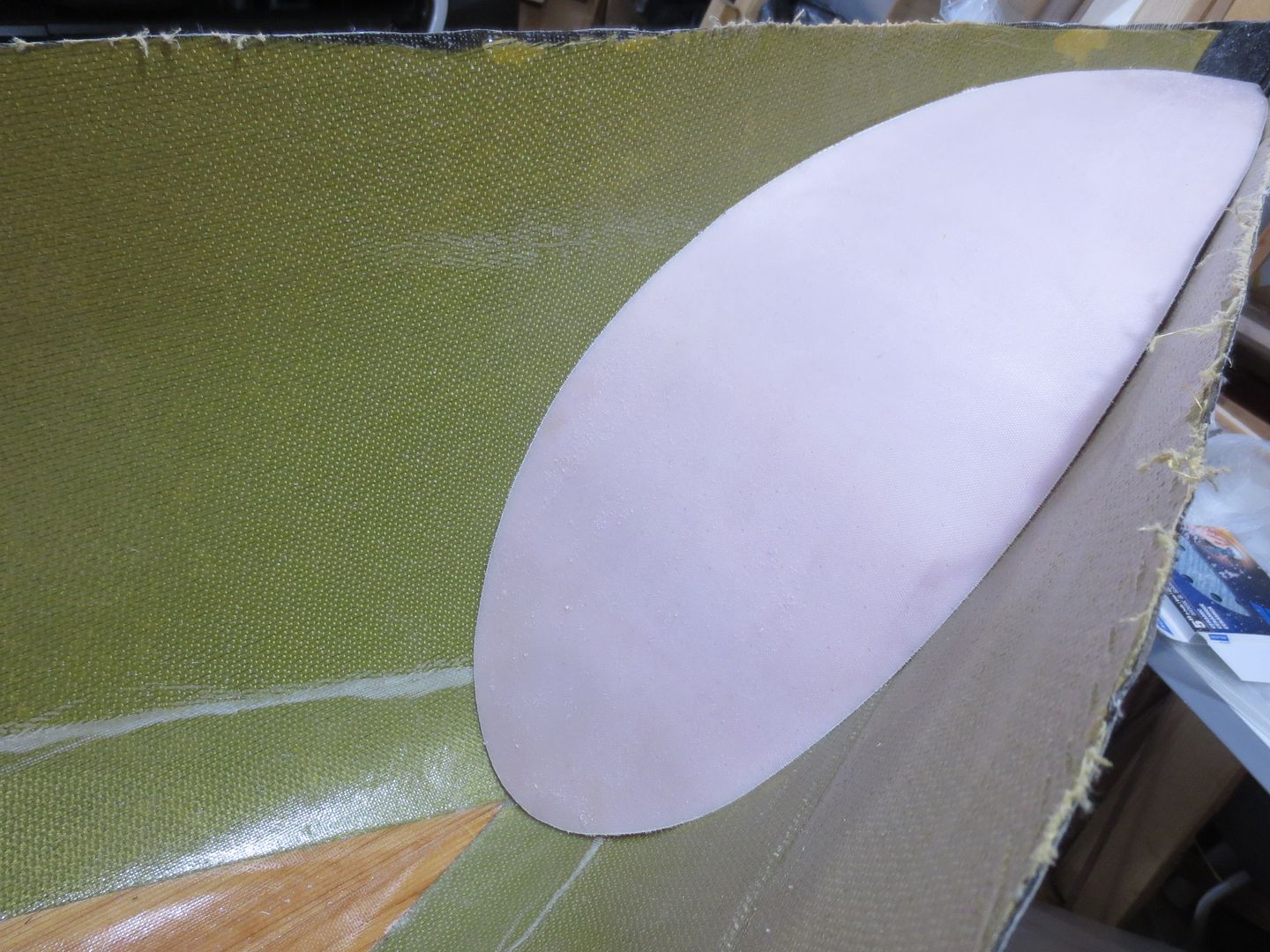

I just finished epoxying in a 1/8" WRC wood insert to add a little more stiffness.

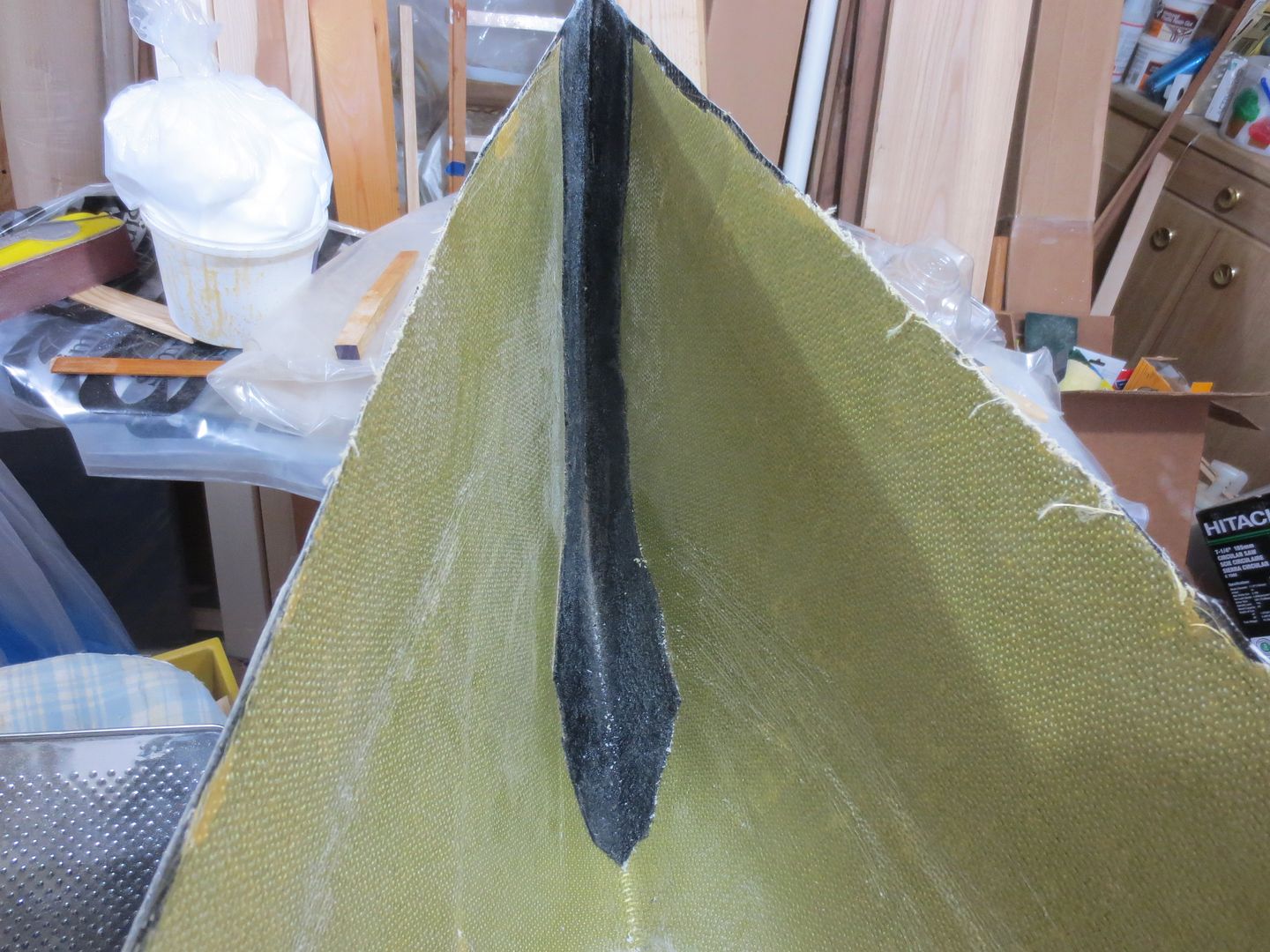

Last pic. I closed the ends with epoxy saturated Polyester sweat shirt fleece. This will not only hold the stems together, but will serve as a Skid plate if I wear through the Kevlar/ Carbon/S-glass layers.

I will add one more layer of cloth over the wood insert. Then flotation chambers and trim. As she sits now Black Pearl weighs 20 lbs 7 oz.

Jim

Here's a few pics.

Covering the stripper with Heat Shrink plastic, and the stems with Electricians tape, as a barrier between the two hulls.

Marking where to cut the Kevlar.

At this point, I have 3 layers of cloth make up the hull. One 5 oz Kevlar, one 6 oz Twill Carbon fiber, and one 6 oz S-glass,

I just finished epoxying in a 1/8" WRC wood insert to add a little more stiffness.

Last pic. I closed the ends with epoxy saturated Polyester sweat shirt fleece. This will not only hold the stems together, but will serve as a Skid plate if I wear through the Kevlar/ Carbon/S-glass layers.

I will add one more layer of cloth over the wood insert. Then flotation chambers and trim. As she sits now Black Pearl weighs 20 lbs 7 oz.

Jim